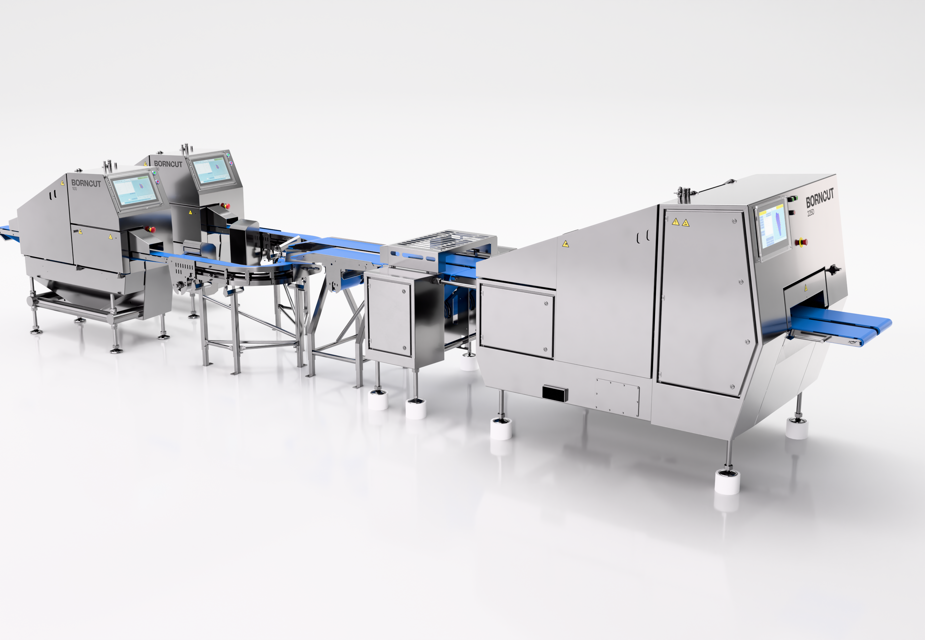

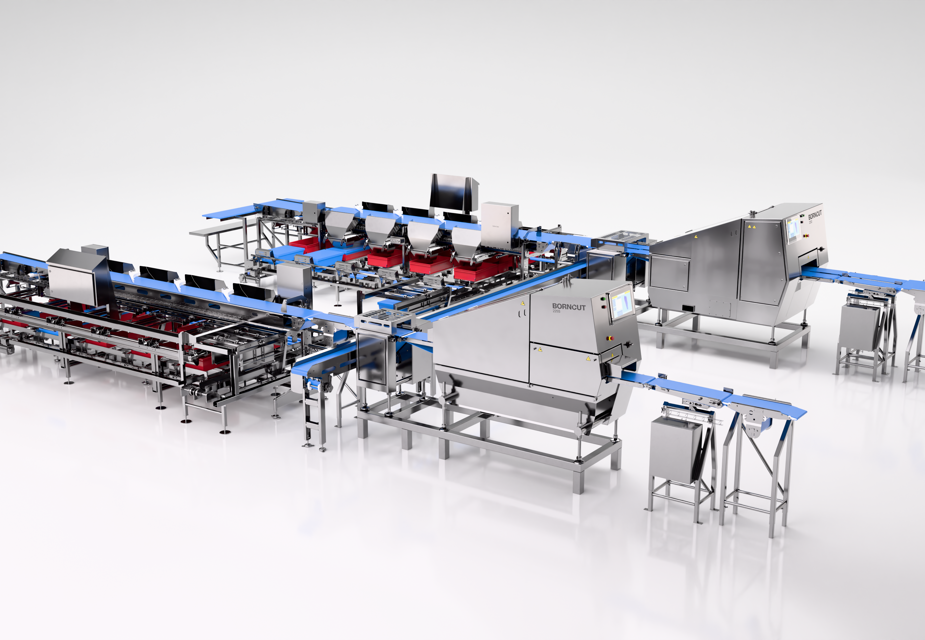

Modular solutions for a smarter, more efficient set-up

We design and manufacture modular add-on equipment that helps food processors build customized production lines. Our high-precision portion cutters—like the BC 100, 300 and 225 series—maximize yield, improve efficiency and reduce waste.

Whether used as standalone machines or integrated into a full production line, our equipment scales with your business. Plus, our intuitive control systems simplify operations by centralizing grading, weighing and sorting in a single interface.

Pieter Korf

Visscher Seafood

“Cost of ownership has been reduced by more than 50%, so we have bought another two machines.”

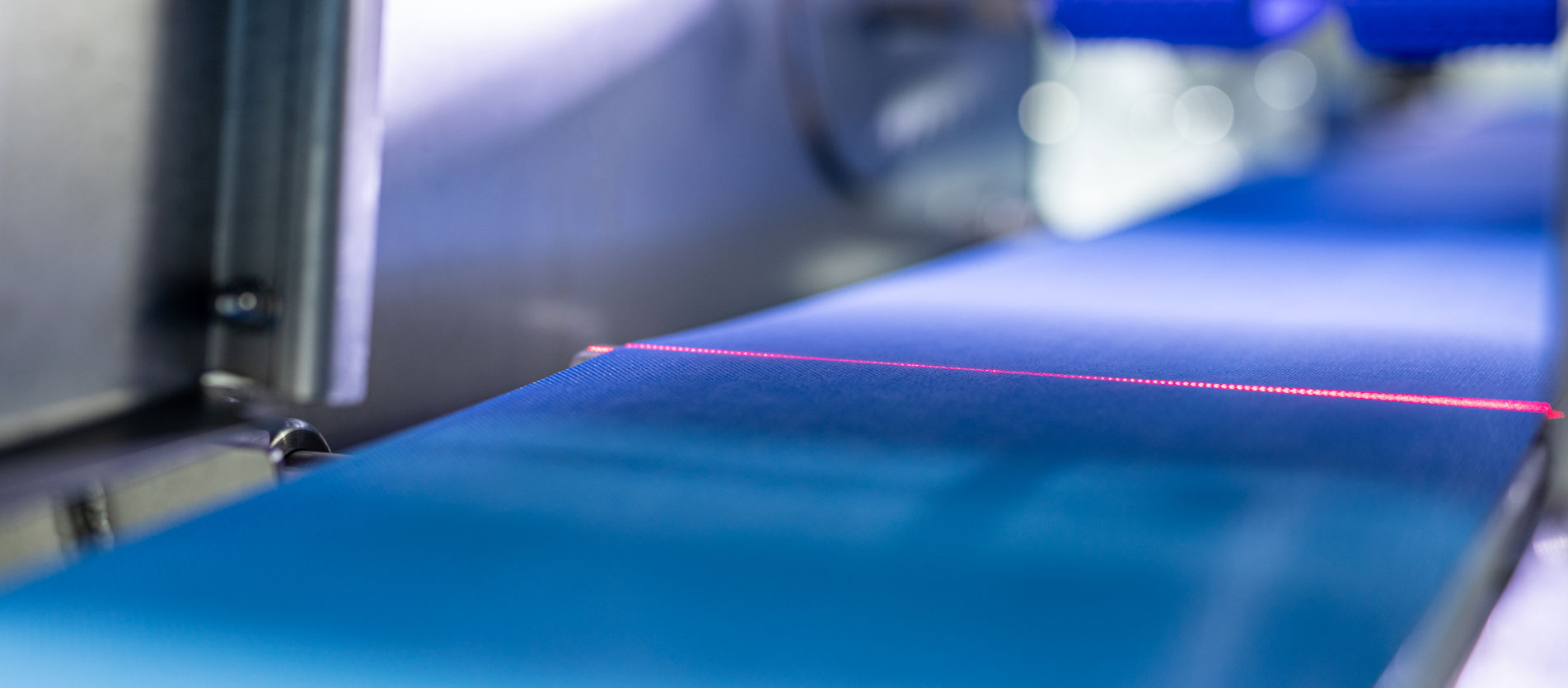

Production control and quality assurance at your fingertips

Find your fit

Fish industry

Borncut’s portioning solutions deliver precise cuts for fish fillets, loins, and cubes while maximizing yield. Our intelligent cutting technology adapts to each fillet’s shape, reducing waste while maintaining texture and quality.

Poultry industry

Maximize efficiency with high-speed poultry portioning solutions from Borncut. Our systems expertly handle fillets, tenders, strips and cubes, ensuring uniform portions with intelligent, precision cutting.

Meat industry

Borncut’s portioning machines cut beef, pork and lamb with precision, optimizing weight control and raw material use. Whether producing steaks, medallions or diced portions, our solutions ensure uniform cuts and high quality.